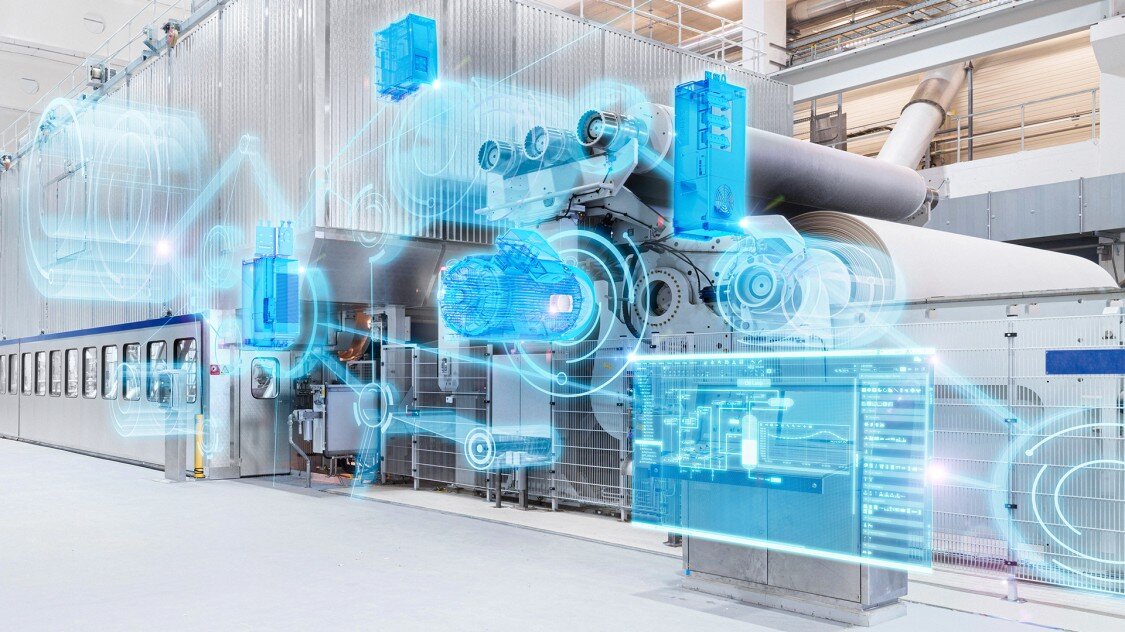

Machine condition monitoring involves monitoring equipment health to detect faults in industrial assets, enabling condition-based and predictive maintenance. This leads to reduced downtime and maintenance costs for industrial equipment like motors, pumps, gearboxes etc. as faults can be identified before catastrophic failures.

The global Machine Condition Monitoring Market is estimated to be valued at US$ 3965.6 Mn in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights.

Market key trends:

Predictive maintenance has emerged as a key trend propelling the machine condition monitoring market. Predictive maintenance leverages machine condition monitoring data to predict potential equipment failures and schedule repairs before faults occur. This helps avoid unexpected downtimes and reduces maintenance costs significantly. Condition monitoring devices collect operating data parameters like vibration levels, temperature, pressure etc. and advanced analytics is applied to this time-series data to detect early signs of defects. As repair needs can be anticipated, downtime during maintenance is minimized. Leading to improved asset utilization and increased productivity. Predictive maintenance offers enormous benefits and its rising adoption across industries like manufacturing, energy, transportation is fueling demand for machine condition monitoring solutions.

SWOT Analysis

Strength: Machine Condition Monitoring helps improve asset reliability and reduce downtimes. It allows remote monitoring and predictive maintenance of machinery.

Weakness: High initial investment costs for installing sensors and monitoring systems. Technical complexity of data analytics may require experienced professionals.

Opportunity: Growing demand from manufacturing and process industries to optimize productivity and minimize maintenance costs. Rising adoption of IoT and connectivity solutions enable new applications.

Threats: Data security risks from networked devices pose cyber threats. Competition from low-cost localized monitoring product offerings.

Key Takeaways

The global Machine Condition Monitoring market is expected to witness high growth. Global Machine Condition Monitoring Market Size estimated to be valued at US$ 3965.6 Mn in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030.

Rapid industrialization and manufacturing activities across developing nations in Asia Pacific and Middle East & Africa are driving the need for predictive maintenance of critical machinery and equipment. The region is expected to grow at the fastest rate during the forecast period due to increasing investments in manufacturing infrastructure from major economies like China, India.

Key players operating in the Machine Condition Monitoring are Applied Sciences Inc., Argon, Emerson, National Instruments, Parker Kittiwake, Meggitt and SKF. They provide proprietary sensor technologies, data analytics platforms and predictive maintenance software to enable remote asset performance monitoring for industries. Adoption of IoT connectivity in devices combined with edge and cloud computing is allowing new machine monitoring applications in automotive, oil & gas, chemicals, utilities and other process industries.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it