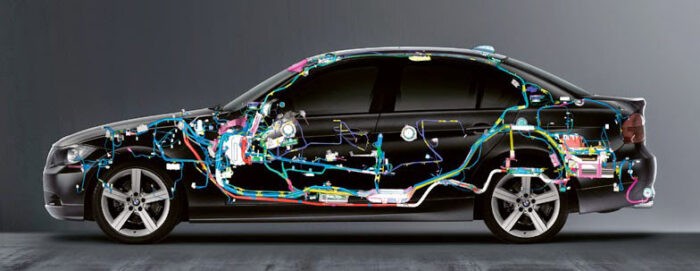

With advances in automotive technology, the role of automotive wiring harnesses has become increasingly important. The wiring harness is often referred to as the nervous system of a vehicle as it connects all of the electrical components together and allows them to communicate.

Evolution of Wiring Harnesses

Early automotive wiring harnesses were relatively basic as vehicles did not rely on electronics as heavily. As few as 30 wires may have been needed to power basic functions like lights, gauges, and ignition. However, as technology advanced, the demand for electronics in vehicles grew dramatically. Modern vehicles can have over 5,000 feet of wiring and several thousand individual wires to support all of the electronic components.

Additional Subsystems Require More Wiring

The introduction and rise of additional vehicle subsystems drove much of the Automotive Wiring Harness complexity growth. Entertainment systems, advanced driver assistance features, and vehicle control units all required their own dedicated wiring. Advanced safety features like airbags also mandated their own robust wiring to ensure reliable deployment. Comfort features like power windows, seats, and locks also connected to the growing bundle of wires.

Manufacturing Standardization

To keep up with demands but also maintain efficiency, automakers standardized wiring harness assembly processes. Common connector types, wire gauges, and routing methods were agreed upon. This allowed for modular design where entire sub-harnesses could be manufactured independently and later combined efficiently. Color coding schemes and consistent pin-outs further streamlined wiring installation tasks.

Data Networking Revolutionizes Harness Design

Perhaps the biggest change came with the adoption of in-vehicle data networks like CAN bus and FlexRay. No longer did every component need a dedicated point-to-point wiring connection. Multiple electronic control units could now communicate over the same paired wires. This greatly reduced wiring complexity and harness size. Automakers have increasingly moved to Ethernet for even higher data rates and expanded networks.

Future Advancements on the Horizon

With autonomous driving looming on the not so distant horizon, wiring harnesses will need to enable even more advanced functionality. Sensor fusion from technologies like lidar, radar and cameras will impose new wiring demands. Over-the-air software updates will likely drive more internet connectivity directly into vehicles as well. Self-driving systems may decentralize some controls, offloading processing power to localized ECUs with their own localized wiring.

Standardization for Plug-and-Play Components

To future proof vehicles and simplify upgrades, more standardized interfaces will be needed between wiring harnesses and exchangeable autonomous driving components. Things like lidar and radar units may connect with common plug-in connectors. This would allow for easy swapping of sensors from different manufacturers. Standard communication protocols could also enable true plug-and-play capability for autonomous driving hardware additions over a vehicle’s lifespan.

Lighter and More Durable Materials

As automakers pursue electrification, weight savings becomes paramount. Next- generation wiring harnesses may utilize super lightweight yet highly durable materials like carbon nanotube based wires. Flexible conductors could further optimize routing. Harnesses may even move integrated control functions and connectors directly onto wiring components for a truly modular architecture. Superior insulation materials may better protect against environmental exposure as well.

From just a few wires powering basic functions, modern automotive wiring harnesses have evolved into complex systems in their own right. Standardization and networking have allowed this growth while maintaining manageable complexity levels. However, enormous changes are just on the horizon as autonomous driving and electrification reshape the industry. Wiring harnesses will be at the forefront of enabling these advances through innovative material, design and integration solutions. Their role as the nervous system and blood vessels delivering power and data throughout vehicles is more important than ever.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it