Introduction to Steel Round Bars

Steel round bars are cylindrical steel bars that are often used in the construction industry as steel reinforcement or in the manufacturing of mechanical parts and equipment. Round bars come in different grades and sizes depending on their intended use. Some common applications of steel round bars include reinforcements in concrete structures, spindles, shafts, joints and other mechanical linkages.

Physical and Mechanical Properties

Steel round bars have several desirable physical and mechanical properties that make them useful construction and manufacturing materials. They have a uniform circular cross-section which allows them to withstand loads from multiple directions with equal strength. They also have high tensile strength allowing them to carry heavy weights safely. Additionally, round bars are highly durable and corrosion resistant making them suitable for use even in harsh outdoor environments and chemical plants.

The strength and ductility of steel round bars depends on factors like the alloy composition, heat treatment processes and surface finishing applied. Carbon steels have moderate strength while alloy steels with additions of chromium, nickel or molybdenum have higher strength. Quenching and tempering processes are commonly used to increase the hardness and wear resistance of bars used in applications involving friction or impact loads. Surface treatments like galvanizing or painting further enhance corrosion resistance.

Grades and Sizes

Steel round bars are available in various standard grades specified based on their chemical composition, mechanical properties and intended applications. Some common grades include low carbon steel, medium carbon steel, alloy steel and stainless steel.

In terms of sizes, steel round bars range from 5 mm to 125 mm in diameter. Selection of appropriate bar size depends on the structural design, loading conditions and safety factors. Thinner bars up to 16 mm diameter are typically used as reinforcements in concrete while heavier duty bars above 20 mm find applications in equipment, machines and heavy structural members. Bars above 50 mm diameter are employed in major load bearing components. Special oversized bars exceeding 100 mm are also manufactured as per project requirements.

Usage in Construction

Steel round bars have widespread application in the construction industry for their high strength, deformability and ductility. Some common construction uses are:

– Concrete reinforcement: Round bars ranging from 6-16 mm are used as longitudinal and shear reinforcements in beams, columns, slabs and foundation works to increase the tensile strength of concrete structures.

– Precast components: Heavier duty bars above 12 mm are used to tension precast prestressed concrete girders and hollow core slabs during manufacturing.

– Piling and retaining walls: Round bars above 20 mm diameter are used as longitudinal reinforcement in concrete and steel piles that are installed in the ground to support heavy structures. They are also used in retaining walls for stability.

– Trusses and lattices: Overlapping round bars of different diameters are welded to form trusses and space lattices for long span roof structures, foot bridges etc.

– Rail tracks: Heat treated alloy steel round bars of grade FE 510 are rolled to exact specifications for use as rails on railway tracks.

– Scaffoldings: As a basic material, round bars of suitable sizes are bent and welded together to form scaffoldings used during construction works.

Thus, the versatile properties and wide range of grades and sizes make steel round bars highly advantageous for concrete reinforcement and prefabrication in construction projects. Their ability to withstand tensile, compressive, shear and bending forces efficiently translates to stronger, safer and durable structures.

Usage in Manufacturing

Besides construction, steel round bars are immensely used as basic engineering materials in various manufacturing industries. Some common applications are:

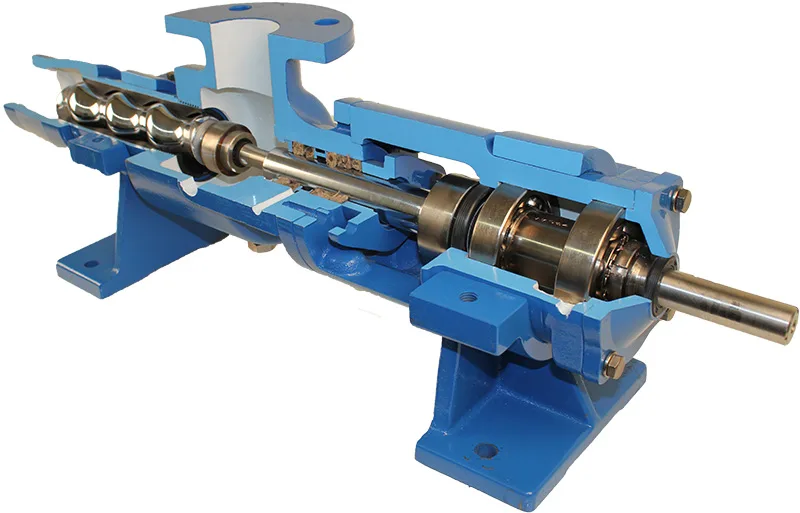

– Machine components: As shafts, spindles, pivots, axles and such rotating or sliding components in machinery which require strength and wear resistance.

– Automotive components: In parts like suspension systems, drive shafts, axles etc. where round bars provide the needed strength with least weight penalty.

– Fasteners: As bolts, screws, pins etc. used to join different components together. Head treated alloy steel grades like EN8, EN24 are commonly used.

– Tools: As handles for hammers, axes, crowbars etc. Tapered round bars are used to manufacture drill bits.

– Pipelines: Along with tubes and angles, round bars are used as structural supports in oil and gas pipeline networks.

– Rebars: Manufacturing of deformed steel bars used in concrete largely employs rerolling and deforming of plain round bars of suitable sizes.

Thus steel round bars form the basic building blocks in a wide spectrum of mechanical, automotive and fabrication industries due to their load bearing ability, machinability and consistent quality meeting varied specifications and standards.

Quality Assurance and Testing

To ensure desired quality, steel round bars undergo several tests before supply as per international and national standards. This includes chemical composition analysis, mechanical properties testing, dimensional checks, surface finish inspection, load testing and non-destructive tests like ultrasonic testing.

Bars are tested for important properties like yield strength, tensile strength, percentage elongation and reduction in area. Magnetic particle or dye penetration tests are carried out to locate surface and subsurface flaws. Quality certified bars conforming to standards like IS 432, ASTM A29, EN 10025 etc are tagged and supplied to industries and construction sites. Proper documentation of testing and certificates give confidence to users.

Regulatory Compliance

Being a basic structural material, production of steel round bars is regulated to ensure safety and consistency in properties. Manufacturing units need to adhere to environmental, health and safety norms prescribed by regulatory bodies.

In many countries, bars used structurally also need to comply with codes and product standards related to concrete reinforcement. Parameters like cover, bar diameter, spacing, lapping and anchorage length etc are specified. Use of quality certified bars conforming to codes is mandatory for safe and long lasting construction works.

Conclusion

Steel round bars are versatile intermediate products widely used in construction as well as mechanical engineering applications. Their availability in different standard sizes, grades and surface finishes along with consistent mechanical properties make them suit diverse structural design needs. Adherence to quality protocols and regulatory standards during manufacturing adds to the reliability and safety of steel round bars as preferred load bearing material in construction of buildings and infrastructure as well as manufacturing industries.

*Note:

- Source: Coherent Market Insights, Public sources, Desk research

- We have leveraged AI tools to mine information and compile it