Introduction to Transmission Systems

Transmission systems are an important component in any automotive vehicle as they allow the engine power to be transferred effectively to the wheels for driving. The primary function of a transmission system is to adapt the output RPM and torque from the engine to the wheel requirements for optimum vehicle performance and fuel efficiency. There are different types of transmission systems commonly used in modern vehicles based on their construction and working principles.

Types of Transmission Systems

The main types of transmission systems used in passenger vehicles are manual transmission, automatic transmission, Continuously Variable Transmission (CVT), dual-clutch transmission and automated manual transmission.

Manual Transmission

A manual transmission is the most basic and oldest type of transmission system. It uses clutch and gear stick for changing gears manually based on speed and load conditions. It allows the driver to select gears directly for precise control over acceleration and deceleration. Most affordable vehicles come with 5-speed or 6-speed manual transmissions which provide better fuel efficiency than automatic transmissions. However, manual transmission requires skill to operate and is less convenient for city driving due to frequent gear changes.

Automatic Transmission

An automatic transmission system selectively changes gears automatically based on inputs from sensors without any direct driver involvement. It uses a hydraulic torque converter instead of a clutch for transferring torque from engine to transmission. Automatic transmission provides ease of driving in city traffic as gears are changed automatically based on throttle input and vehicle speed. However, it is less fuel efficient compared to manual transmission and costs more due to the complex hydraulic and electronic control systems. Modern automatics have 6-8 forward speeds for improved fuel efficiency and performance.

Continuously Variable Transmission (CVT)

A CVT provides continuous range of effective gear ratios between maximum and minimum ratios allowing stepless adjustment of gear ratio helping the engine operate at optimal RPM at all times. A CVT uses steel push belt or chain traveling between two variable-diameter pulleys for transferring power. It provides excellent acceleration and fuel efficiency but lacks robustness and is more expensive than traditional transmission types. Nissan, Subaru vehicles use CVT widely.

Dual-clutch Transmission

A dual-clutch transmission uses two separate clutches and gear sets inside for odd and even gears. It changes gears more rapidly than single-clutch automated manual transmissions and provides the smoothness of an automatic along with better performance and fuel efficiency through optimized gear ratio selection. Dual-clutch transmissions require complex controls but are preferred in high-performance vehicles. Volkswagen, Hyundai vehicles use this transmission popularly.

Automated Manual Transmission

It is a more advanced form of manual transmission which uses electro-hydraulic system for automatic clutch operation, gear selection and gear shifts for efficiency and convenience comparable to automatic transmissions. Driver can still select gears manually or let the system do it automatically. Honda developed this technology originally but most failed practically due to reliability issues.

Working Mechanism of Major Transmission Types

Understanding their detailed working mechanism is essential for analyzing their merits and demerits:

Manual Transmission Mechanism

It consists of gear stick, clutch pedal, main shaft, counter shaft, synchronized gears and gear selector forks. The clutch pedal is pressed for disengaging the engine from transmission during gear change using gear stick. The selected gear is engaged to main shaft using synchronizers providing smooth engagement. this allows transmission of power to drive wheels.

Automatic Transmission Mechanism

It uses planetary gear sets, brake bands, clutches and torque converter instead of clutch pedal. A governor/sensors monitor engine load and vehicle speed which controls solenoids operating the hydraulic circuit. This presses/releases clutches and brake bands inside for smooth gear shifts without driver input. Fluid coupling of torque converter transfers power smoothly.

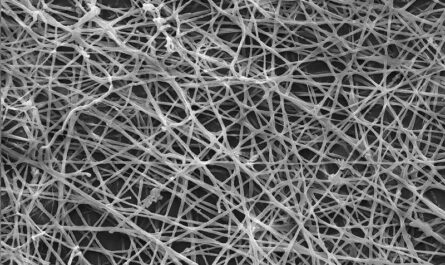

CVT Mechanism

It uses two variable diameter pulleys connected to input and output shafts. A push belt rides on the pulleys for power transmission. By changing pulley diameters electrically, effective gear ratio can be varied continuously. This maintains engine in optimal rpm range for efficient performance and lower fuel consumption.

Dual-clutch Transmission Mechanism

It uses two separate clutch and gear assemblies—one for odd gears and other for even gears. During gearshifts, the next needed gear is preselected and engaged by the second clutch while driving clutch disengages. This provides instantaneous gear changes like paddle-shift transmissions but with full automation.

Transmission Control Systems

Modern transmission systems integrate complex electronic and hydraulic control systems for optimized, automated gear shifts. Sensors monitor critical parameters like throttle position, vehicle speed, engine loads etc. A Transmission Control Unit (TCU) processes these signals and actuates solenoids operating hydraulic valve body and clutch packs for seamless gear changes via precise line pressure control. On-board diagnostics systems ensure transmission reliability and performance.

Safety and Maintenance

Making necessary transmission fluid changes regularly using manufacturer specified fluid is vital. Overfilling or incorrect fluid selection could affect transmission life. Early identification of faults through dash warnings and addressing them promptly helps avoid breakdowns impacting safety. Checking mounting bolts periodically prevents oil leaks. Timely replacement of worn components like clutches ensures transmission efficiency and durability.

Conclusion

This overview of major automatic transmission system types showed their working differences delivering diverse performance attributes. Choosing the right transmission involves considerations like intended usage, vehicle class, operating conditions etc. Advancements in automatic transmissions are making them more efficient and affordable while CVTs and dual-clutch autos offer cutting-edge technologies aiding drivability and lower emissions. Proper maintenance remains critical for maximizing transmission and vehicle lifespan.

*Note:

- Source: Coherent Market Insights, Public sources, Desk research

- We have leveraged AI tools to mine information and compile it