Mid-infrared (mid-IR) sensors are an emerging class of photon detectors that harness the mid-wavelength infrared spectrum. By detecting light in the 3-15 micrometre range, these advanced optical and thermal sensors enable groundbreaking applications across several industries. Let us delve deeper into the capabilities and future potential of mid-IR technologies.

Types of Mid-IR Sensors

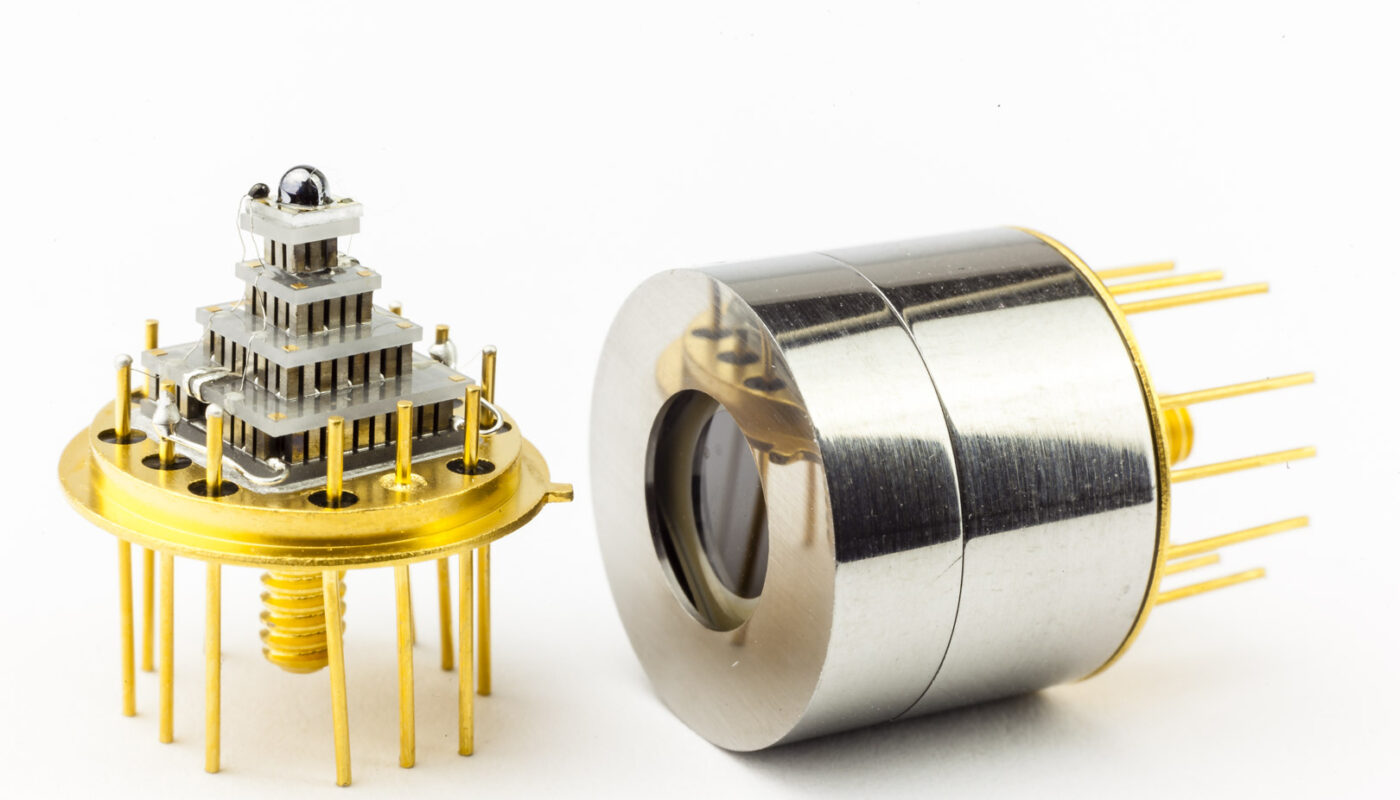

There are two primary types of Mid-IR Sensors – thermal detectors and photon detectors. Thermal detectors such as microbolometers measure the heat emitted by objects and do not require cooling. They are commonly used in applications like thermal cameras. On the other hand, photon detectors like mercury cadmium telluride (MCT) and indium gallium arsenide (InGaAs) detect photons in the mid-IR spectrum. Photon detectors offer superior sensitivity and spectral resolution compared to thermal detectors but require cryogenic cooling.

Applications in Medical Imaging

Thermography using mid-IR cameras enables precise medical imaging applications without contacting the patient or using ionizing radiation. Thermal imaging helps doctors detect injuries, inflammatory conditions, tumours and infections more effectively. It has proven useful in breast cancer screening, diagnosis of burn severity, and peripheral vascular disease detection. Combined with artificial intelligence, thermal cameras can also automate disease screening and diagnosis. Ongoing research aims to expand medical thermography into new areas like cardiology, orthopaedics and dentistry.

Defense and Security

Thermal cameras mounted on drones, helicopters and ground vehicles allow defense forces to conduct round-the-clock covert surveillance even in complete darkness. Such cameras aid in tasks like perimeter monitoring, intruder detection and search & rescue operations. Moreover, advanced mid-IR sensors integrated with algorithms for target recognition are helping develop next-gen thermal weapon sights, driver’s vision enhancers and threat detection systems. Several countermeasures also leverage thermal signatures to detect camouflaged targets, tunnels and improvised explosive devices (IEDs).

Process Monitoring and Quality Control

Thermal imagers find extensive usage in industrial process monitoring by detecting thermal irregularitiesinvisible to the naked eye. They help identify hot or cold spots indicating potential maintenance issues, energy losses or quality control problems. Various manufacturing sectors ranging from oil & gas, steel, semiconductor fabrication to pharmaceuticals rely on thermography for preventive maintenance, remote equipment monitoring, and accurate non-destructive testing. Likewise, sophisticated mid-IR sensors paired with machine learning analyse material properties, compositions and defects during production.

Environmental Monitoring

Advanced mid-IR spectroscopy techniques play a key role in environmental monitoring. Gas filtering coronagraphs and high-resolution infrared spectrometers detect trace atmospheric gases to study climate change. Meanwhile, airborne and satellite-based sensors monitor greenhouse gas emissions, air pollution levels as well as map wildfires, volcanic activity and vegetation health globally. Thermal cameras are also being tested for renewable energy assessment through roof inspections and monitoring solar thermal plants. Overall, mid-IR environmental monitoring tools gather vital scientific data for sustainability efforts.

Challenges and Advancements

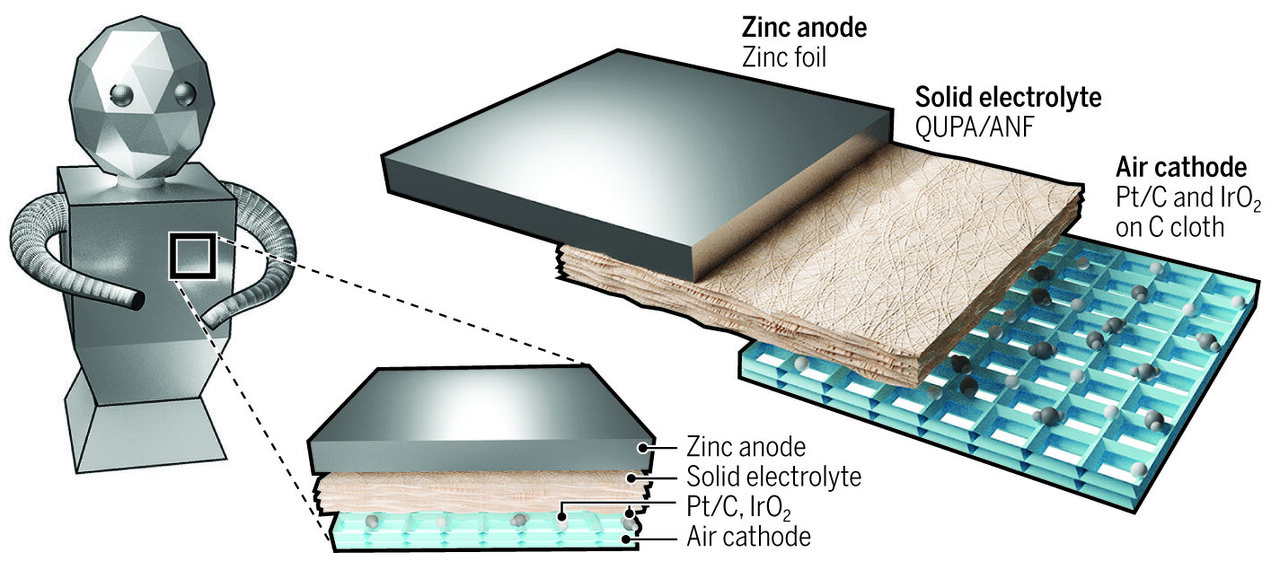

Though mid-IR technologies present enormous opportunities, further innovation is required to address challenges such as high sensor costs, limited wavelength range, and cooling requirements. Novel nanomaterials like quantum cascade structures enable uncooled operation and wavelength tuneability. Advances in microfabrication processes and detector materials are continuously shrinking sizes and lowering power needs of mid-IR components. Multispectral designs combining visible, NIR and mid-IR spectra further enrich diagnostic capabilities. Continued R&D aims to realize smarter, more affordable mid-IR systems for expanding their socioeconomic impact across industries.

Future Prospects

As mid-IR Sensores techniques mature, their integration into diverse platforms will emerge. Novel mid-IR cameras, spectrometers and laser-based lidars onboard aerial, ground and underwater robots/vehicles will enhance situational awareness and remote monitoring networks. Implantable biomedical nanosensors may non-invasively track vital signs and metabolite levels. Next-gen smartphones could gain enhanced vision, photovoltaic inspection and health diagnostics via embedded mid-IR imaging. Advanced driver-assistance systems may leverage thermal perception to “see” in adverse weather and traffic conditions. Overall, mid-IR photonics will transform many fields by enriching what humans and machines can “see” beyond the visible spectrum.

In summary, mid-IR technologies offer revolutionary new detection capabilities with applications across industries. Considerable advancements have already expanded mid-IR imaging usage in domains like medical diagnosis, industrial monitoring, environmental science and defense. Going forward, further sensor miniaturization, lowered manufacturing costs alongside multidisciplinary research efforts should help realize the true potential of mid-IR photonics. They will undoubtedly play a pivotal role in enabling transformative applications for science, healthcare, public safety and more in the coming decade.

Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it