Industrial Garnet – A Versatile Abrasive Used Across Diverse Industries

What is Garnet?

Garnet is a group of silicate minerals that form isometric crystals. Its chemical composition varies widely with the most common garnets being almandine, spessartine, pyrope, grossular and uvarovite. Garnet crystallizes in the cubic system, though they are often found in hexagonal form as well. The colors displayed by garnets vary from deep red to orange-yellow depending on exact composition. Majority garnets mined today are used for industrial purposes rather than gemstones.

Key Properties of Garnet

Garnets exhibit excellent hardness of around 6.5–7.5 on Mohs hardness scale which makes them suitable for abrasive applications. They have good resistance to weathering and corrosion due to their chemical stability. Garnet possesses high density in the range of 3.6 to 4.3 g/cm3 providing heavy media separation. Importantly, garnet is electropositively charged allowing it to be readily separated from other negatively charged minerals. These unique physical and chemical properties of garnet lead to its widespread industrial applications.

Uses of Garnet as Abrasive

Abrasive blasting: Garnet is commonly used as an abrasive for blasting applications like surface preparation, decorative finishes and paint removal. Its hardness results in effective cleaning without damaging substrate material. Garnet produces less dust and Sharp angular shape ensures consistent surface finish.

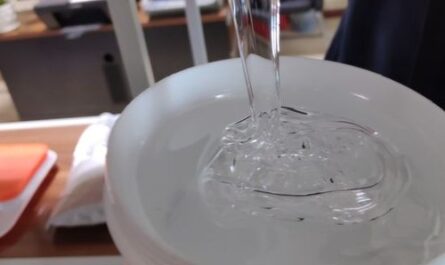

Abrasive waterjet cutting: Finely powdered garnet is mixed with high-pressure waterjets to accurately cut hard and brittle materials like stone, ceramic and glass. Compared to other abrasives, garnet produces smoother edges and reduces substrate damage.

Abrasive powders: Crushed and graded garnet powders find applications for finishing of metals, grinding of non-metals, lapping, honing and polishing. Non-toxic nature makes it suitable for precision tasks in industries like optics manufacturing.

Abrasive wheels: Encapsulating garnet grit in resin-based bonded wheels is used for a wide range of grinding operations across industries like automotive, aerospace and fabrication of tools, dies and molds. It’s durable and economical for medium to fine finishing.

Blasting Media in Mining Industry

Due to its hardness and resistance to weathering, garnet is an excellent abrasive for various mining applications:

Shot blasting at mines: Used to clean mining and excavating equipment, garnet blast media helps remove scale, rust and coatings without damaging base material. Ideal for blast cleaning prior to painting.

Heavy media separation: Fine garnet powder provides optimum suspension properties for separation of various minerals based on specific gravity differences. This helps in concentration of valuable ore in mineral processing.

Other Uses

Expanding usage of garnet includes water filtration, sand blasting at shipyards, abrasive mandrels for centerless grinding, abrasive additive for honing sticks and as abrasive particles in waterjet machining. Emerpging applications are being developed in areas such as compound semiconductors polishing and finishing of ceramics and silicon wafers.

Along with providing critical abrasive requirements across industries, garnet mining also supports hundreds of livelihoods and makes economic contributions in major garnet producing regions worldwide. Steady growth of wind energy and solar panel installation will further boost garnet demand with increasing need for precision surface finishing and cutting applications. The well-balanced properties of garnet ensuring economic and eco-friendly production continues to expand its applications portfolio.