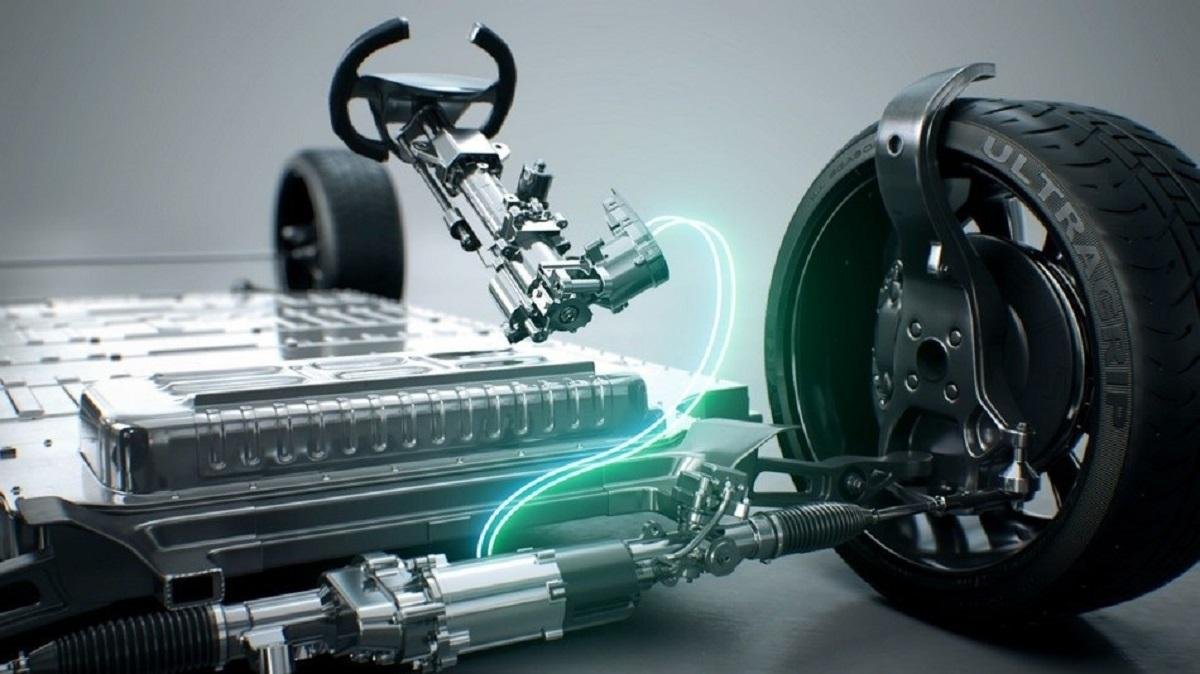

Automotive technology has come a long way from the initial introduction of manually operated vehicles. One of the major evolutions has been the shift from traditional mechanically linked controls to electronic drive-by-wire systems. Drive-by-wire refers to the replacement of traditional mechanical control systems like throttle cables, brakes lines and steering columns with electrical interfaces and electronic controls.

The evolution of controls

In the early days of cars, all vehicle controls like throttles, brakes and steering were directly linked through mechanical parts like cables and rods. However, over the decades, these direct links started getting replaced with electronic interfaces. One of the earliest adoptions was replacing the carburetor with fuel injection which introduced electronic fuel controls. Brake-by-wire systems then eliminated the direct hydraulic link between brake pedal and calipers. Steering-by-wire followed suit removing the traditional steering column and coupling it with electronic power steering. Completing this evolution is throttle-by-wire which utilises drive-by-wire to control engine power electronically based on various driver and vehicle sensors.

Benefits of drive-by-wire systems

By replacing the direct mechanical links, Drive by Wire introduces several advantages over traditional setups:

– Improved vehicle dynamics and stability: Electronic controls enable features like Torque Vectoring, Electronic Stability Control etc which improves handling.

– Enhanced safety: Removing linkage between controls add safety layers like advanced crash detection and braking.

– Increased design flexibility: Without physical pedals and columns, interior packaging is freed up for innovative cockpit designs.

– Improved drivability: Electronic throttle control enhances responsiveness and makes operations smoother.

– Reduced maintenance: Electronic interfaces are more reliable than worn out cables and joints over long term usage.

– Self-driving compatibility: Drive-by-wire infrastructure seamlessly interfaces with autonomous driving technologies.

Challenges in implementation

While the benefits are enticing, drive-by-wire systems also present some implementation challenges:

– Increased complexity: Adding electronics and digital controlling raises general vehicle complexity.

– Single point failures: A software or sensor glitch could potentially immobilize all controls at once.

– Expense: Developing and integrating such advanced systems increases costs significantly for automakers.

-Legacy compatibility issues: Drive-by-wire needs to interface with older mechanical hardware during transition periods.

– Cyber security risks: Connected electronic controls are susceptible to hacks and privacy threats.

The future is drive-by-wire

Despite the initial difficulties, most experts believe drive-by-wire represents the future of vehicle control architecture. Several top automakers have already developed working prototypes and some even productionized certain drive-by-wire subsystems. As the technology matures with innovations happening at a rapid pace, full vehicle drive-by-wire capabilities are expected to be commonplace in mass market vehicles within this decade. The developments will allow seamless transitions between manual, autonomous and shared mobility modes. In the coming years, drive-by-wire will complete the shift from purely mechanical to fully electronic vehicle operation paving way for the next generation smart, connected and driver-optional vehicles.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it