Dimethylolpropionic acid (DMPA) is an industrially important chemical that finds wide application in the field of coating formulations.

What is DMPA?

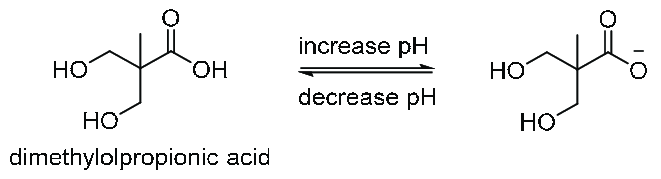

DMPA, also known as 2,2-bis(hydroxymethyl)propionic acid, is an organic compound with formula C5H10O4. It is a colorless solid that is soluble in water and various organic solvents. DMPA contains two hydroxymethyl functional groups attached to a propanoic acid group, giving it three active sites for chemical reactions.

Due to the presence of multiple reactive sites, DMPA acts as a branching monomer that enables the formation of three-dimensional polymeric structures upon curing. The hydroxyl groups allow it to undergo polycondensation or polyaddition reactions with difunctional molecules like diisocyanates or diepoxides. This reactive branching property of DMPA is key to developing advanced thermosetting coating technologies.

Applications in Coatings

One of the major applications of DMPA is in water-based polyurethane dispersions where it serves as a chain extender and crosslinker. Upon curing, DMPA reacts with diisocyanates to form a highly networked, urethane-modified polyacrylate network structure within the coating film. This network structure imparts outstanding corrosion resistance, chemical resistance, hardness and other protective properties to the cured film. DMPA-extended waterborne polyurethanes are commonly used as industrial maintenance coatings and original equipment manufacturer (OEM) coatings.

DMPA also finds use as a curing agent for epoxy resins used in high-performance adhesives and coatings. It reacts with epoxide groups to form a densely crosslinked thermosetting network. DMPA-cured epoxy coatings exhibit excellent adhesion, flexibility, corrosion resistance and chemical resistance. They are often used in applications like marine anti-fouling paints, automotive topcoats, and metal finishing protective coatings.

Another major coating application of DMPA is in polyester-melamine coatings systems. Here, DMPA serves as a crosslinker that branches the linear polyester backbone upon reaction with melamine resin under curing. The resulting highly crosslinked polyester-melamine network provides outstanding gloss retention, hardness, flexibility and resistance to chemicals like acids and alkalis. These coatings are commonly used for metal housewares, appliances, automotive components and industrial applications.

Advantages over Alternatives

While other difunctional compounds like diethanolamine, triethanolamine and ethylenediamine can also impart branching in coatings, DMPA offers some distinct advantages:

– Higher reactivity: The proximity of functional groups in Dimethylolpropionic Acid allows for faster curing kinetics compared to alternatives. This enables low temperature or energetic curing.

– Improved properties: The compact three-dimensional networks formed by DMPA branching lead to coatings with optimized mechanical, barrier and corrosion resistant properties.

– Environmental friendliness: Being derived from renewable succinic acid, DMPA has a favorable life-cycle assessment profile compared to petrochemical chain extenders.

– Versatility: DMPA is compatible with a wide range of resin systems like polyurethanes, epoxies, acrylics, melamines etc. enabling its use across various coating technologies.

– Regulatory compliance: DMPA meets strict regulatory requirements pertaining to coatings used in applications like food contact, potable water contact etc.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it