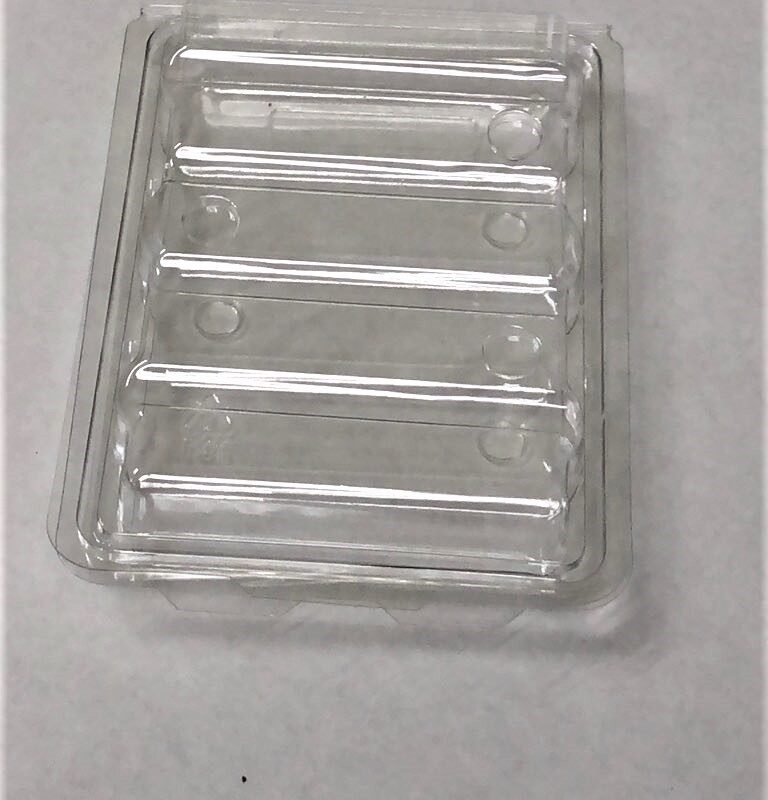

What is Blister Packaging?

Blister packaging is a term used to describe clamshell plastic packaging which consists of aformed plastic “blister” which holds the product securely in place. A paper or plastic backing is then heat-sealed or cold-sealed over the plastic blister to hold it firmly in place. This type of packaging provides individual, pre-formed cavities or pockets for each item.

Benefits of Blister Packaging

Blister packaging offers several benefits for both product manufacturers and consumers. Some key advantages include:

– Tamper Evidence: Blisters clearly show if a package has been opened before, providing important tamper evidence for products like medications. The sealed paper or plastic film provides a clear indicator if the package has been compromised.

– Protects from Damage: Each item is securely held in an individual cavity, protecting it from damage due to crushing, impact or abrasion that may occur during transportation and handling. This is particularly important for fragile or breakable items.

– Easy to Store and Transport: Blister Packaging take up less space than traditional boxes while still maintaining protection of individual items. They are lightweight yet very durable, making them cost effective to ship and easy for retailers to store large volumes on shelves.

– Improved Product Shelf Life: The air-tight packaging helps preserve product freshness longer by providing an effective moisture and oxygen barrier. Medications and foods have a better shelf life when packaged in blisters.

– Allows Clear Product Viewing: Most blister pack materials are clear, allowing full product visibility without having to open the package. Consumers can see exactly what they are purchasing before buying.

– Easy to Open: Packages peel open easily along the seal line for convenient “on-the-go” access to individual items without needing scissors. The backing material stays fully intact when opened.

Common Applications of Blister Packaging

Blister packaging has proven effective for a variety of product types. Here are some of its most popular applications:

– Tablets and Capsules: Pharmaceuticals, supplements and vitamins are excellently suited for blister packaging due to its tamper proof properties, product protection and ease of dosing individual tablets or capsules.

– Hardware Items: Small parts like screws, bolts, nuts and washers are securely held in blisters to prevent loss or breakage. Mechanics and DIYers appreciate having specific parts readily accessible.

– Food Items: Hard candies, coated chocolates, dried fruits/nuts and snacks maintain freshness in blisters until opened for individual serving portions. Some baking ingredients are also sold this way.

– Electronic Components: Small components for electronics, like batteries, fuses, wire connectors etc. benefit greatly from the protection of blister packaging during shipping and handling.

– Personal Care Products: Small toiletry items like cotton swabs, Band-Aids, sanitary pads/tampons, contact lenses and more which need to be kept clean and hygienic are well-suited to individual blister cavities.

– Collectibles and Memorabilia: Coins, stamps, trading cards and the like displayed attractively through clear blister packaging are popular with collectors.

Blister Packaging Materials

A variety of materials are used to produce thermoformed blister packs depending on the specific application requirements:

– Plastic Blisters: The most common type is made from clear, transparent PET (polyethylene terephthalate) or PVC (polyvinyl chloride) plastic which can be easily formed to any shape needed.

– Paper/Paperboard Backings: Coated or laminated paper, paperboard or foamboard provides a cost-effective solution for backing most thermoformed plastic blisters.

– Aluminum Foil: Used as a backing material where a complete moisture and gas barrier is required, such as for desiccants or oxygen-sensitive items.

– Plastic Films: Clear or opaque plastic films like PVC, PET or polypropylene offer tear/puncture resistance and are thermoformable. Popular for lidding blister packs.

– Lidding Techniques: Materials can be heat-sealed, cold-sealed, adhesive-sealed or welded/fused over the blister depending on content.

Custom Options for Blister Packaging

Blister packs are popularly custom-manufactured to unique product sizes, shapes and specifications. Key options include:

– Size and Shape: Pockets can be any geometric shape needed from round to square to fit any product dimensions precisely.

– Color and Graphics: Plastic blisters and film lids easily accept pre-printed design and color patterns specific to company/branding.

– Special Tooling: Complex blister molds can be fabricated for intricate or odd-shaped items common to certain industries.

– Peel-Away Films: Some lidding films are engineered to pull away cleanly for convenience while others remain fully attached.

– Multi-Cavity Blisters: Used to bundle related items together in a single package like samples, trial sizes or assortments.

– Tamper Evident Seals/Tabs: Commonly added to indicate if package has been previously opened before purchase.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it