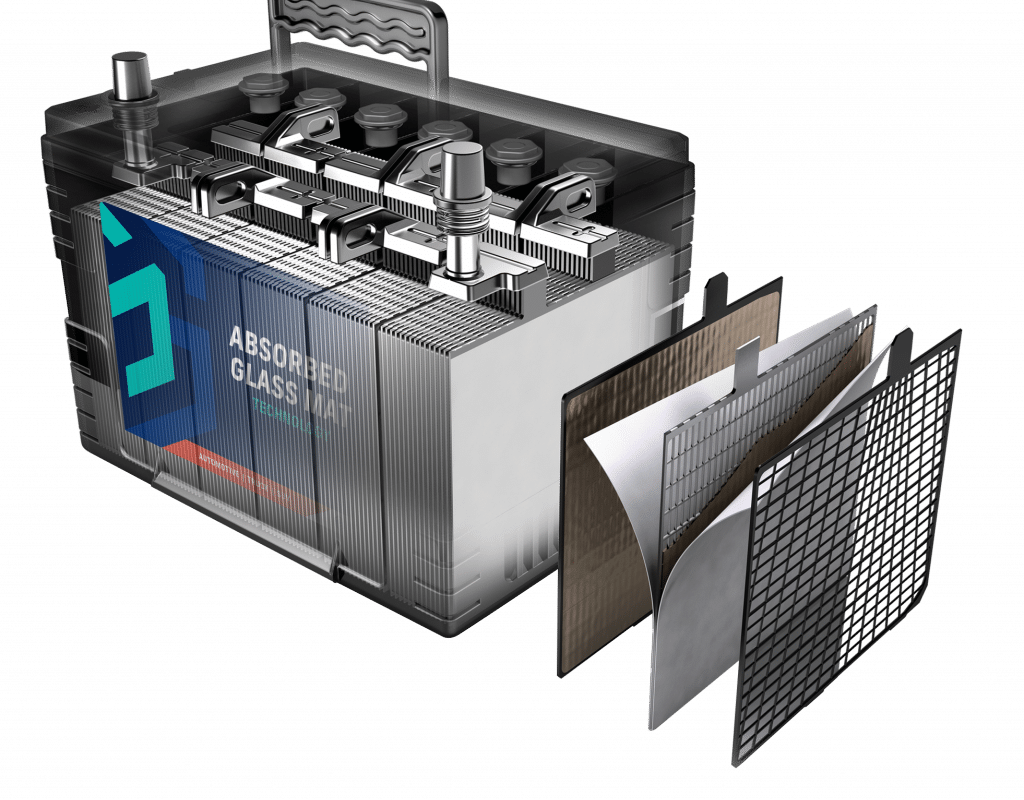

The Absorbent Glass Mat (AGM) battery is a type of lead-acid rechargeable battery that is commonly used in vehicles such as cars, motorcycles, boats, and other equipment that uses lead-acid batteries. The AGM battery differs from a conventional flooded lead-acid battery in that it uses absorbent glass mats between the plates to separate the acid from the plate and prevent acid sloshing during movement or operation.

Working of an AGM Battery

In an AGM battery, thin separators made of microfine fiberglass mats are used instead of liquid electrolyte. These fiberglass mats are highly porous and capable of absorbing and immobilizing the sulfuric acid electrolyte through capillary action. When the battery is charged, the absorbed electrolyte permits the flow of current between the plates by the same electrochemical process that occurs in a flooded battery. During discharge, the sulfuric acid remains in the glass mats and is not free to slosh around.

The absorbent glass separators absorb and hold the electrolyte in place between the lead plates, preventing acid stratification and equalizing pressure within the closed battery case. This immobilized electrolyte configuration results in improved battery performance during vibrations or movements compared to traditional flooded batteries. The immobility of the electrolyte also means that AGMs can be mounted in any orientation and do not require careful handling and maintenance of fluid levels.

Advantages of AGM Batteries

Maintenance-Free Operation: Unlike flooded batteries, Absorbent Glass Mat Battery do not require any water replenishment. The electrolyte is absorbed and held together in glass mats, eliminating water loss concerns.

Vibration Resistance: Thanks to the immobilized electrolyte, AGM batteries are highly resilient to vibration and movement effects experienced in vehicles. This makes them suitable for motorcyles, boats, and other applications with vibration-prone environments.

Multiple Mounting Orientations: The inability of electrolyte to slosh around allows AGM batteries to be securely mounted in any position, whether upright, sideways or upside-down.

Low Self-Discharge: With no water loss occurring, the self-discharge rate of AGMs is less than 2% per month at 20°C, lower than flooded lead-acid batteries.

Improved Cycle Life: On an average, AGM batteries last over 500 charge-discharge cycles, much higher than regular flooded lead-acid batteries.

Deep Discharge Recovery: AGMs can easily recover from deep discharge and do not develop “memory effect” like NiCad batteries.

Applications of AGM Batteries

Motor bikes and Scooters: Due to their maintenance-free operation and resistance to vibration, AGM batteries are the ideal application for motorcycles and scooters which face great deal of motion during operation.

Boats and Marine: Mobility of the boat and exposure to water makes Absorbent Glass Mat Battery preferred choice over flooded batteries for marine applications.

UPS and Inverters: Backup power applications like UPS systems benefit from low self-discharge and deep cycle discharge ability of AGM batteries.

Electric Vehicles: Electric cars increasingly rely on AGM batteries for their maintenance-free operations and tolerance to multi-axis movements.

Solar Power Systems: Off-grid solar power backups utilize AGM batteries to ensure reliable electric supply despite occasional cloud cover.

Telecom Towers: Remote base station towers mounted AGM batteries for their consistent performance despite exposure to weather extremes.

Drawbacks of AGM batteries

Higher Upfront Cost: AGMs are more expensive than conventional flooded lead-acid batteries of equivalent power rating due to use of advanced absorbent separators.

Slower Charge Acceptance: During bulk charge, AGMs take 30-50% longer to fully charge compared to flooded batteries of same amp-hour rating.

Improper Handling Risks: Mishandling AGMs, especially overcharging, can cause premature failure through decomposition of glass mats or plates shedding active material.

With maintenance-free operations, high tolerance to shocks and vibrations, wide mounting orientations and deep cycle discharge ability, AGM batteries have established themselves as a popular and reliable solution in automotive as well as backup power applications. While costlier initially, their longer service life and consistent performance offsets the higher upfront expense. Further advancements continue to make them more efficient and lighter for various industrial and consumer product applications.

*Note:

1. Source: Coherent Market Insights, Public sources, Desk research

2. We have leveraged AI tools to mine information and compile it